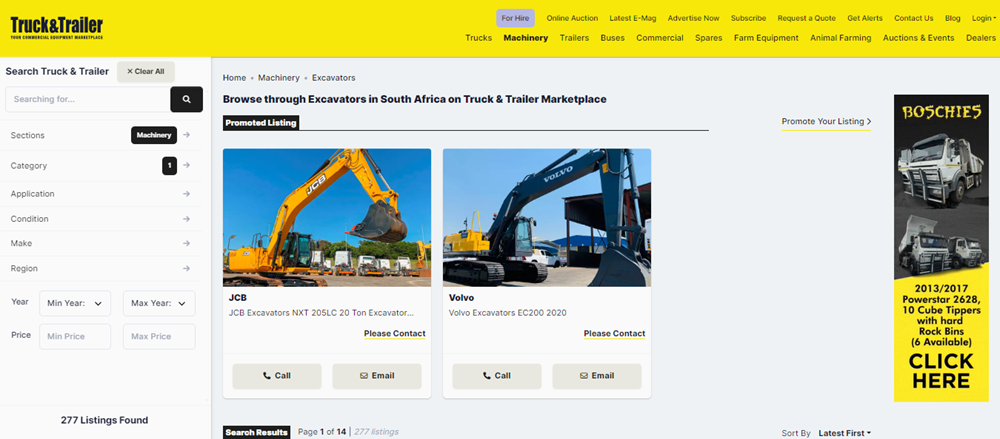

Operating an excavator is a skill that requires precision, expertise, and a deep understanding of safety protocols. Whether you're a seasoned excavator operator or a novice looking to embark on this heavy machinery journey, it's crucial to prioritise safety to ensure a smooth and incident-free operation. Now, we'll look into essential tips for safely operating an excavator, shedding light on best practices that cater specifically to the market. Are you unable to find any machinery equipment on Truck & Trailer that you require for your business? So that dealers can see there is a demand for it, log a request for it.

Understanding the Basics of Safely Excavator Operation

To safely operate an excavator, it is crucial to have a comprehensive understanding of its basic components and controls. Familiarise yourself with the machine's levers, pedals, and buttons, as well as their respective functions. Furthermore, take the time to study the excavator's operator manual to fully comprehend its capabilities.

Tips for Operating an Excavator Safely

- Conduct Thorough Pre-Operation Checks

Before the excavator's engine roars to life, take the time to perform a comprehensive pre-operation inspection. Check for any visible damages, leaks, or loose components. Ensure that all fluid levels are within the recommended range, and examine the tracks or wheels for signs of wear and tear. This meticulous examination significantly reduces the risk of mechanical failures during operation.

- Familiarise Yourself with the Excavator Controls

Understanding the intricacies of an excavator's controls is fundamental for safe and efficient operation. Familiarise yourself with the joystick, foot pedals, and various switches. Practice controlling the boom, arm, and bucket to develop a nuanced feel for the machine's movements. This familiarity will enhance your precision and help prevent accidental damage to surroundings or utilities.

- Mindful Site Analysis

Before you commence digging, conduct a thorough analysis of the site. Identify potential hazards such as underground utilities, unstable terrain, or overhead obstacles. South Africa's diverse landscapes demand a keen awareness of the surroundings. Utilise site plans and consult with project managers or utility companies to ensure a comprehensive understanding of the work environment.

- Wear Proper Personal Protective Equipment (PPE)

Personal safety should never be compromised. Always wear the appropriate personal protective equipment, including a hard hat, high-visibility clothing, steel-toed boots, and gloves. In the South African context, where weather conditions can vary, be prepared for extreme temperatures by donning appropriate attire, such as sun hats or insulated gear.

- Set Up a Dedicated Communication System

Clear communication is key, especially in large construction sites. Establish a reliable communication system, such as two-way radios, to stay in constant contact with ground personnel, supervisors, or fellow operators. This ensures that everyone is on the same page, minimising the risk of accidents and enhancing overall coordination.

- Mind the Load Capacity

Every excavator has a specified load capacity, and exceeding this limit can lead to instability and potential disasters. Prioritise safety by strictly adhering to the manufacturer's guidelines regarding load capacities. Regularly check the load charts and ensure that you are within the safe operating limits for the specific model of excavator you are using.

- Gradual Movements and Precise Operation

Smooth and controlled movements are critical when operating an excavator. Avoid sudden or jerky motions, as this can lead to instability and potential accidents. Take the time to plan your movements, especially when navigating tight spaces or working in proximity to other equipment. Precision in operation not only enhances safety but also contributes to the efficiency of the overall project.

Photo by Prostooleh on Freepik

Photo by Prostooleh on Freepik

- Stay Aware of Environmental Conditions

Environmental conditions can greatly impact excavator operation. In our country, where weather conditions can be unpredictable, operators must stay vigilant. Heavy rains can make surfaces slippery, while extreme heat may affect the machine's performance. Stay informed about the weather forecast and be prepared to adjust your operation accordingly. Additionally, be cautious of potential wildlife in the area, as encounters with animals can pose risks to both the operator and the equipment.

- Regular Equipment Maintenance

Proper maintenance is the backbone of a safe and efficient excavation operation. Follow the manufacturer's maintenance schedule meticulously, and address any issues promptly. Regularly inspect and lubricate moving parts, check hydraulic systems, and ensure that all safety features are in optimal condition. A well-maintained excavator is less likely to encounter unexpected breakdowns, reducing the chances of accidents on the job site.

Read: Unearth Excellence: A Guide to Excavator Maintenance Best Practices

- Emergency Response Plan

Despite meticulous planning and adherence to safety measures, emergencies can still occur. Establish a comprehensive emergency response plan that includes protocols for various scenarios, such as equipment malfunction, injuries, or unforeseen hazards. Ensure that all personnel on the job site are familiar with the emergency procedures, and conduct regular drills to reinforce a quick and efficient response in critical situations.

- Continuous Training and Skill Development

The field of excavation is ever-evolving, with advancements in technology and safety standards. Invest in continuous training for excavator operators to keep them updated on the latest industry practices and innovations. Regular training sessions enhance operators' skills, increase their awareness of safety protocols, and contribute to the overall efficiency and productivity of the operation.

Read: How to Maximise Excavator Productivity

- Respect Work Zone Boundaries

Clearly define work zones and establish clear boundaries to prevent unauthorised personnel from entering potentially hazardous areas. Implement visual indicators, such as cones, barriers, or signs, to demarcate the boundaries of the excavation site. This not only protects bystanders but also ensures that all team members are aware of their proximity to operating machinery.

In conclusion, mastering the art of operating an excavator in South Africa requires a combination of technical expertise and a commitment to safety. By conducting thorough pre-operation checks, familiarising yourself with the controls, analysing the site, wearing proper PPE, establishing communication systems, minding the load capacity, and ensuring gradual and precise movements, you contribute to a safer and more productive work environment.

Remember, safety should always be the top priority. Whether you're a seasoned professional or just starting your journey as an excavator operator, incorporating these tips into your routine will not only protect you and those around you but also contribute to the overall success of your projects. Unable to find any machinery equipment on Truck & Trailer that you require for your business? Log a request for it. So that dealers can see there is a demand for it.

Read Related Articles

- Unearth Excellence: A Guide to Excavator Maintenance Best Practices

- TLB vs Excavator: Which Machine Is Best for Your Project?

- How to Maximise Excavator Productivity

- The Benefits of Using an Excavator for Landscaping Projects

- Excavator vs Wheel Loaders: The battle of the beasts

- 6 Types of excavators

- 11 types of excavation methods used in the construction industry